Sand castings, lost wax casting in vacuum or air, Disamatic, squeeze cast, forged or die cast.

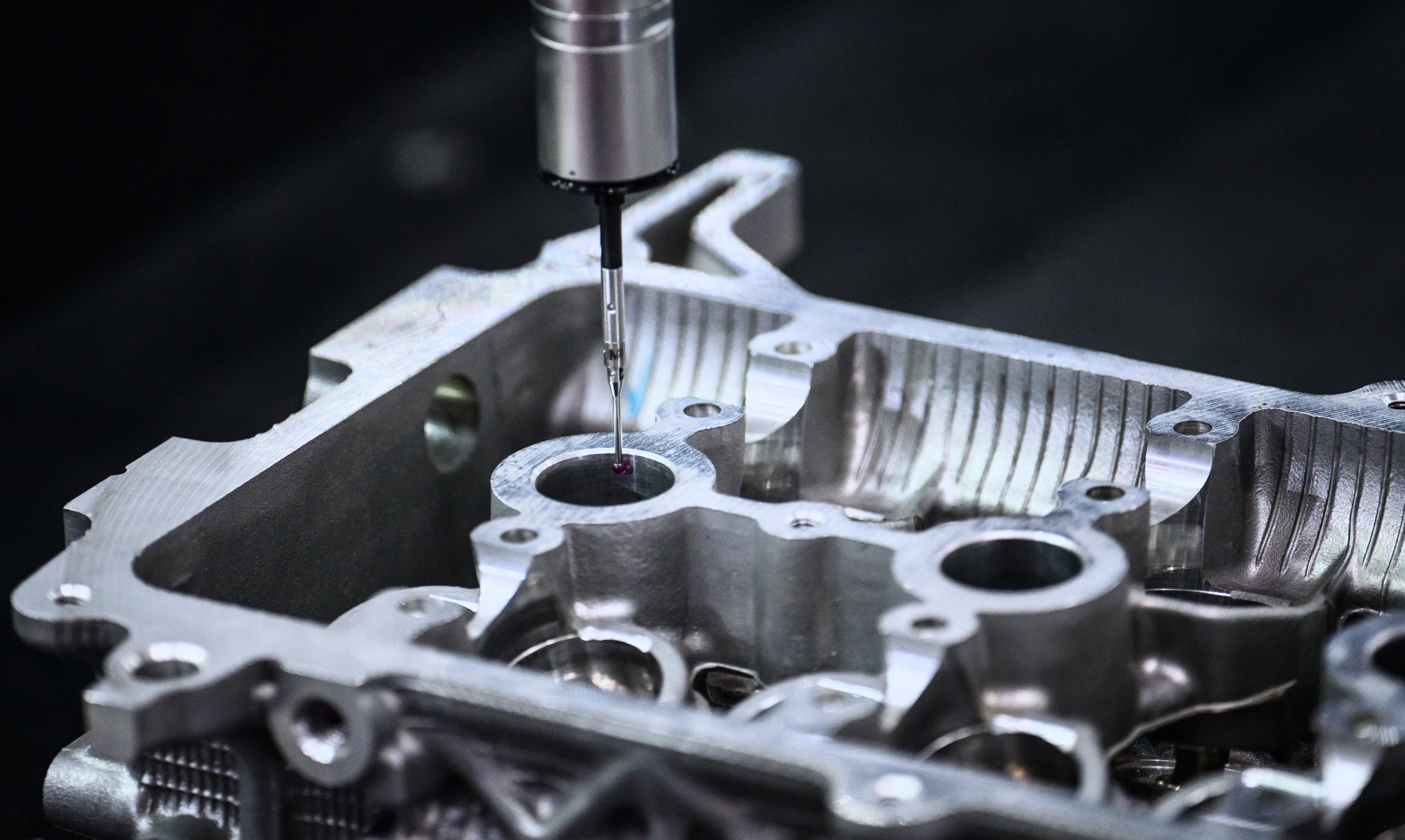

Machining includes spark erosion, CNC milling, turning and drilling. Fabrications include welding, press brake, laser and water jet cutting, flame cutting, sub assembly and full assembly.

Heat treatment includes rapid quench, carbon controlled atmospheres, flame hardening and hot isostatic pressing.

Galvanising, sheradising, painting, anodising, zinc plating, polyester coating and hand polishing from N4 to mirror finish.

Plastic injection and blow moulding in ABS, glass filled.

If you do not see what you require listed above, please email us with your request.

– BSEN10293:2005

– BSEN1559-1:1997

– BSEN1559-2:2000

– BSEN10025:1993

– BSENISO1461:1999

– BS970 Part1:1996

– BSEN10025:1993

– BS4921:1988

– BSEN 13811:2003

– ASTM 487/A 487M – 93

– A 890/A 890M 2003

– B108-06, A 703/ 703M

– ASTM A380

– Norsok M-501 June 2004

– Extrusions – aluminium/plastic, cold stampings, forgings

– Fabrications in sheet steel. Pre-fabricated assemblies

– Plastic blow moulding and plastic pressure die casting